Tianyi Mould company has so many important points and all of them must be well done during the mold manufacturing.

The action included:

-Inquiry from customer before fan mold manufacturing.

During this processing, the communicators of both sides should offer the correct information or specification to be sure that the pricing and technical points are meeting buyer's requirements.

-During the Manufacturing, the designer needs to be responsible to make the mold design,he has to consider how the customer use this fan mould, how to design the fan mould into long life tool, how to design the related components to make it easier tooling during the Fan Mould Manufacturing and higher precision.

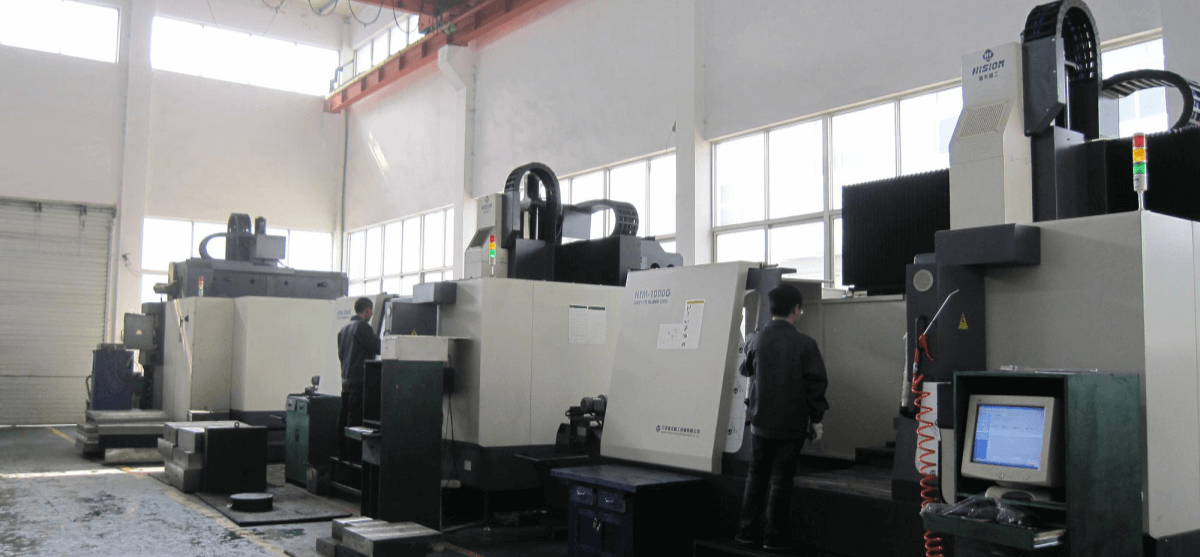

-Mould components machining during the Mold Manufacturing.

The machine operators with strong responsibilities, then the mould components can be precise enough to meet the drawings tolerance requirements. Here the responsibilities are indicated by careful steel installation, rigorous machining process following and rigorous dimension controlling during and after the machining. Eliminate the wrong points into the next process to ensure the delivery time of the order.

-Mould components dimension controlling after the machining. During the Manufacturing, the cavities, cores and other mold components, after the machining, they need serious dimension controlling. QC team is responsible to be sure that all the dimensions are according with the drawings.

-Mould assembling workshop, all of them they need to be responsible to be sure that the Mould Manufacturing is successful and the delivered fan mould is top quality according with company standard.

Tianyi Mould is a responsible mold manufacturer, this kept company continues developing, and Tianyi fan mould teams are keeping the biggest responsibilities to customer, considering the customer's willing, doing what customer needs. And Tianyi People are also known locally responsible for themselves,for their family, for their organization and for their community.